Company profile

As one of the leading manufacturers of environmental friendly fireproof decoration material in the Pearl River Delta of China, Foshan Sanshui Tian Nuo Lian Cheng Decoration Material Co., Ltd. is a large-scale stock company specializing in manufacturing and selling various decoration material having above a decade of experience. The Company is located in the Dongcheng Development Zone, east of Yanbu River of Sanshui, Foshan, Guangdong. As at the entrance of the freeway and near the cargo site of the railway, the Company enjoys advantageous traffic and geographic condition. Its production base is situated in the Leping Town Technological Industrial Zone, Sanshui District, covers an area of 60Mu and has modernized wo-rkshops Its main products include building decoration purpose aluminum single plates, aluminum screen walls, aluminum ceilings, aluminum buckle plates, Light steel keels and baking finish keels etc.As a member of China Building Decoration Association, the Company has its products win a number of honors such as the Recommended Products by China Building Material & Project Construction Assoc-iation, Quality Reliable Product certified by China Medium & Light Industrial Products Quality Assurance Center and China Famous & Excellent Product certified by World Excellent Brands Recommen-dation Center. Tian Nuo Lian Cheng products are the top priority for environmental friendly fireproof decoration material.

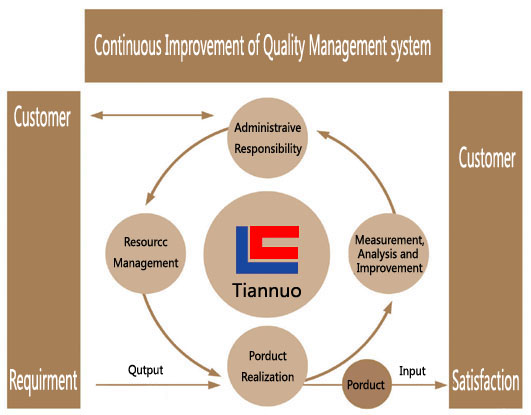

Sanshui TianNuo LianCheng Decoration Material Co., Ltd passed ISO9001:2000 quality system certification of British Boeing Company.The management level of the Company is composed of experienced high-quality talents and they carry out management and operation following ISO9001:2000 quality system. Its products sell to the whole nation and are applied in tens of large-sized buildings e.g. in Beijing, Zhengzhou, Shenyang, Shandong, Wuhan,Taiyuan, Hangzhou, Xinjiang, Kunming, Hainan, Shenzhen, Zhuhai, Guangzhou etc., w-inning clients' unanimous recognition.

The company has strong technical strength, with large-scale production equipment with the world advanced level, high degree of automation; CNC shearing machine, CNC bending machine, automatic punching machine and other products, advanced equipment and testing means. In 2014 the introduction of a fully automatic sheet metal production line from Sava Jhnny company in Italy, the number of the company's production quality, speeding the development of customers from home to office extended to the professional market, airport, subway etc..

Persisting in the quality rule of "human centered, technique updated, management strengthened, and improvement maintained", Nanhai Tian Nuo Lian Cheng Decoration Material Co., Ltd. wishes to closely cooperate with clients and the likes in the same trade to devote to the exploration of a new world in decoration.

Idea

Management

The Company continuously improves and optimizes its quality management system, always pays attention to the demands of users and the market and carries out strict product test, an-alysis and improvement. It also makes detailed and concrete division of management obligations, incorporating effective resource management and related value added activities, all of which ensures the excellence of product quality and increases clients' satisfaction.

To focus on user benefits and social benefits, strengthen quality control, improve the detection means, therefore, the company strictly in accordance with the ISO9001 quality management and quality assurance system, each main production process adopts a very strict quality inspection. At the same time, the company has professional testing laboratory, the introduction of sophisticated detection and test equipment and technical personnel, in accordance with American buildings manufacturers association (AAMA2605-98 standard) on the metal coating requires a quality inspection and testing of all items

1. Coating thickness test,

2. Color chromatic aberration test,

3. Adhesive forec pane test,

4. Pencil hardness test,

5. Solvent resistant test,

6. Impact resistant test,

7. Luster test.

The indexes of paint spraying of the Company meet AAMA2605-98 requirements.

Certificate

Inspection reports

Browse